Compression Fittings Technical Data

Metal Sealing

Compression Fittings employ metal sealing mechanism and are exclusive for metric tube; they come in series of “L” and “S” (for light-duty and heavy-duty respectively); see table below for their selection.

Compression Fittings Installation Instructions

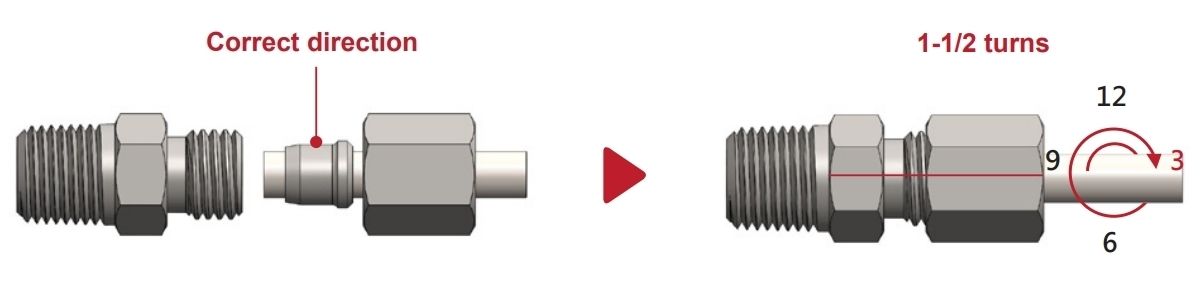

1. Apply anti-seize lubricant to the threads of the fitting body. 2. Slide nut and ring onto the tube in sequence and in correct direction. 3. Insert the tube into the fitting body. 4. Make on the body and nut after finger-tightening the nut. Wrench the nut 1-1/2 turns

Pressure Load: L / S series selection

1. Pressure: select appropriate series according to desired pressure. 2. Space: select series based on available space

| Series | L | S |

|---|---|---|

| Design | Light / Thin | Heavy / Thick |

| Pressure | 100~250kgf/cm2 | 250~400kgf/cm2 |

| Suitable for heavy-duty applications | Good | Excellent |

| Tube Size | 6, 8,10,12,15,18,22,28,35,42mm | 6,8,10,12,14,16,20,25,30,38mm |

| Tightening Torque | Normal | High |

| Applications | Machines tools, agricultural equipment, trucks | Hydraulic press, injection molding, machinery, metallurgy, shipbuilding, engineering machinery |